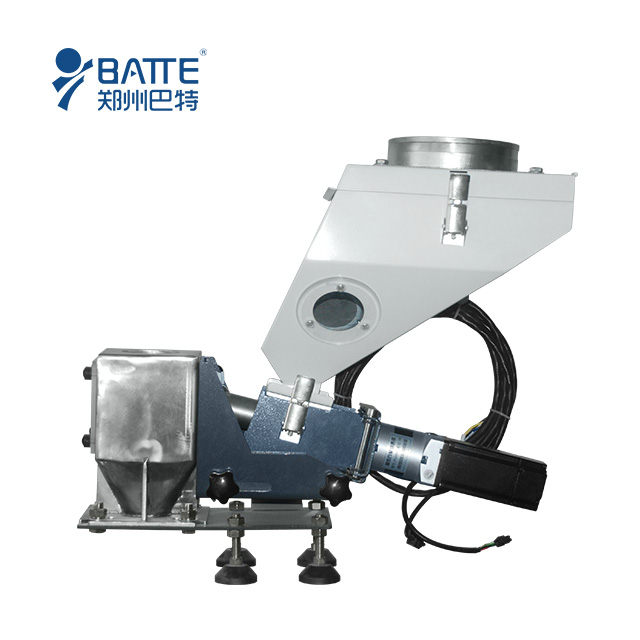

continuous loss in weight gravimetric feeder for extruder

Loss-in-Weight Extrusion Feeder High-accuracy, cost-effective one-component masterbatch and additive gravity feeder for injection molding machines, extruders and blow molding machines, providing plastic manufacturers with significant cost savings and production Efficiency advantage.

Powder particle continuous gravimetric loss in weight feeder The external hopper acts as a protective shell for the internal hopper; preventing operator contact, airflow and other factors from interfering with the weighing accuracy of the load cell. The mechanical separation of the weigh chamber from the screw feeder, motor and additive feeder provides additive feeding precision and accuracy unmatched in the industry. The loss-in-weight feeder consists of a feeding system, a feeder (single and double shaft screw feeders), a weighing system and a stirring system. In operation, the hopper, material and feeder are continuously weighed together. As the material is delivered, the actual weight loss rate is measured and compared to the desired weight loss rate (setpoint). Deviations from the set point are automatically corrected by adjusting the feeder rate. Thus, the material can be fed continuously and uniformly and accurately.

The loss in weight feeder machine is mainly used for the addition of micro powder, main material or auxiliary material. like:

1. In the food industry: trace additives such as brightener, ADA, Vc, emulsifier, enzyme preparation, and addition of main ingredients (such as flour, toner, cocoa powder, powdered sugar, etc.);

2. The addition of main materials or auxiliary materials in plastics, medicine, chemical industry, and pharmaceutical industries.

3. Environment: exhaust gas purification, water treatment, diesel particulate filtration, etc.

The static accuracy of the loss-in-weight feeder system reaches 0.1%; the dynamic accuracy of linearity and repeatability reaches 0.3%, welcome to inquire. info@battemachinery.com