Application of loss-in-weight feeder in plastic synthesis industry

Application of loss-in-weight feeder in plastic synthesis industry

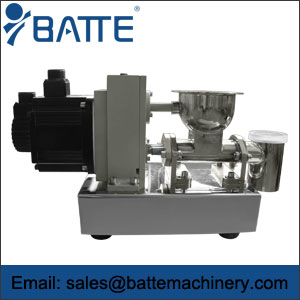

The production of plastics consists of many important processes, and many different kinds of raw materials can generate a homogeneous special plastic compound through these processes. The plastic synthesis process is a continuous process. The main steps include: feeding, plasticizing/melting, stirring, homogenization, mixing, dispersion, degassing, reaction, heating/cooling, etc. In fact, feeding is a key step. The main raw materials must be supplied continuously and accurately during the production process. The company's loss-in-weight feeder uses mature weighing technology and unique control software, enabling users to obtain continuous, reliable and accurate results. The spherical hopper improves the feeding accuracy and performance of the material with good fluidity, and the material with poor fluidity uses a specially designed agitator to ensure the uninterrupted operation of the equipment. The feeder equipped with the control device of the designed design is simple to install, and its multi-functional characteristics have been further improved.

Compared with past premixed feedstocks, the new process formula contains lower wax content or no wax at all. This shows that high-performance plastic synthesis technology can not only increase output and quality, but also reduce raw material costs, which is in line with the purpose of modified plastics production plants. The company has developed a complete set of feeding screws to provide correct feeding treatment solutions for various materials, and the simple and fast replaceable screw improves the flexibility of the process, service life and superior performance.