Automatic metering feeder control

In the production of chemical fiber, it is often required to put solid powdered raw materials into the process equipment with a constant basin. If the feeding is intermittent (e.g. PVA dissolution in vinylon production, nylon pot dissolution in nylon production, etc.), then the quantitative feeding is automatically or manually carried out by means of a weighing scale, if the feeding is continuous (e.g. PVA is delivered to the dissolving machine in the washing section of vinylon production), in order to balance the feeding machine, unit The feeder amount of time should be kept constant, so automatic control of feed quantity is needed. Here, the whole control system of PVA feeding to dissolver is taken as a concrete example of automatic fixed t feeder control.

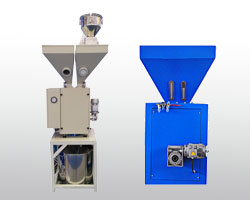

First, the principle of the feeder machine.

PVA, which is planted in the basin conveyor belt from the middle of PVA, has a unit length of Q (kg/m). Obviously, the weight t per unit length is related to the material level in PVA. When the material level is high, the blanking will be more, the material layer is thicker, the Q is bigger, on the contrary, the Q is smaller. As can be seen from Fig. 2113, the rotational speed of the feeding device in the middle trough is synchronous with the metering conveyor belt. When the conveyor belt speed is 2 (2/min), the rotational speed of the feeding device is also fast and the blanking rate is large. Therefore, it can be considered that the thickness of the material layer on the conveyor belt, i.e. the weight Q per unit length, is not affected by the speed of the conveyor belt.

When Q fluctuates, the feeder torque W can be kept constant as long as the feeder speed V is changed. PVA automatic feeder control is based on this basic principle. Therefore, changing the feeding speed library is the control function of the system.